About

As human activities continue to release substantial amounts of carbon dioxide (CO2) into the atmosphere, Carbon Capture and Storage serves as a method to mitigate the impact of greenhouse gas emissions.

Can Carbon Capture and Storage Decarbonise the Cement Sector in Developed and Emerging Economies?

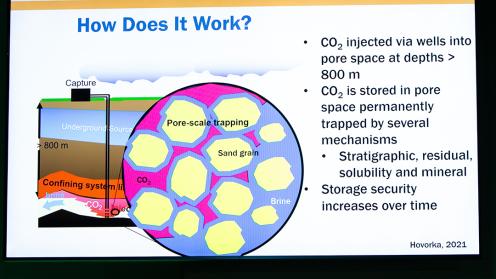

Carbon capture and storage (CCS) and carbon capture, utilization, and storage (CCUS) are crucial technological solutions in the fight against the climate change. As human activities continue to release substantial amounts of carbon dioxide (CO2) into the atmosphere, CCS serves as a method to mitigate the impact of these emissions. The process involves capturing CO2 emissions from industrial sources, such as power plants and factories, before they are released into the air. Once captured, the CO2 is transported and securely stored underground in geological formations, preventing its release into the atmosphere and contribution to the greenhouse effect.

This event convened to discuss CCS and CCUS in the context of cement production processes. Speakers considered the question, “Can the CCS developments in developed economies mature the technology to help the cement sector in developing economies?”

In a welcome statement, Brad Crabtree, US Department of Energy, noted that while the cement industry is a high CO2 emitter, it has shaped our world and remains essential to modern lives. He drew attention to recent climate and infrastructure legislation in the US which includes approximately USD 12 billion in funding to support CCS projects. He underlined the importance of deploying low-cost technologies to make CCS accessible and affordable for developing countries.

Tim Dixon, IEA Greenhouse Gas R&D Programme (IEAGHG), set the scene by describing the CCS value chain, which includes CO2 capture, transport and injection into geological structures deep within the ground. He reported that legislation is a key area for increased CCS deployment, and that the Sixth Assessment Report of the Intergovernmental Panel on Climate Change builds a case for CCS deployment. He further drew attention to the IEA CCUS Handbook, which identifies priority issues that legal frameworks should address for CCUS deployment. He noted that CCS continues to fall short of the 2030 target.

Katherine Romanak, University of Texas at Austin, reported on research to determine whether stored CO2 can leak and associated impacts if it does. CO2 stored underground, she noted, becomes mineralized into rock over time. She underscored that studies have shown that even though CO2 leakage is unlikely, any leakage into drinking water would lead to carbonation of the water—which is benign. Regarding impact on terrestrial organisms, she noted that plants with developed root systems are more resilient, and that microbes diversity tends to change towards acid tolerant species.

Beth Hardy-Valiaho, International CCS Knowledge Centre, discussed the case study of Heidelberg Materials’ CCUS project in Edmonton,Canada, as a first-mover initiative in the cement industry creating a full-scale carbon capture project. The project, she noted, will capture over one million tonnes of CO2 annually from cement production processes. She highlighted that stakeholder consultations reveal that Indigenous Peoples and local communities expressed interest in being involved in the project.

Discussing efforts to build momentum for CCS deployment in the Central Eastern Europe (CEE) region, Jonas Helseth, Director, Bellona Europa, noted that such technologies are paramount for just transition to ensure sustaining jobs in industries. Noting the lack of CCS topics in mainstream debates on climate policies in the region, he presented the CCS4CEE project aimed at promoting discussions on long-term CCS deployment. He further pointed out the need for long-term national strategies and plans, and mentioned plans to link the CEE CCS project to the cement industry, with the objective of storing five million tonnes of CO2 by 2030.

Ruth Herbert, Carbon Capture and Storage Association, presented CCUS projects to decarbonize the cement industry in the UK. She reported buy-in from workers unions on CCUS projects due to benefits to job markets. These include, she added, the creation of 70,000 job opportunities from the cement industry, while protecting another 77,000 jobs in the steel, cement, chemicals, ceramics, and glass industries. She presented a case study of Hanson’s Padeswood Cement Works as an example, noting that it aims to capture and store 800,000 tonnes of CO2 per year.

Claude Lorea, Global Cement and Concrete Association, said CCUS is the single most important technology to decarbonize “hard to abate” sectors such as the cement industry. She emphasized that applicable technologies for this exist, but a business case for their wider deployment requires government support, including low procurement policies and inclusion of renewable energy in cement industry processes. She reported that CCUS adoption in the cement industry remains critical to achieving net zero emissions and needs to be scaled up from less than 1% to 90% by 2050.

Organizers: IEAGHG, University of Texas, CCSA, International CCS Knowledge Centre, Bellona

Contact Person: Katherine Romanak | katherine.romanak@beg.utexas.edu

More Info: https://ieaghg.org/

To receive free coverage of global environmental events delivered to your inbox, subscribe to the ENB Update newsletter.

All ENB photos are free to use with attribution. For this COP 28 side event, please use: Photo by IISD/ENB | Angeles Estrada Vigil